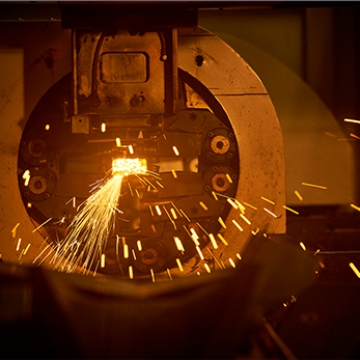

TUBE LASER CUTTING

Laser cutting technology enables you to fabricate high volume and high-quality tubular and box section components in rapid turnarounds times, eliminating the need for traditional fabrication methods.

What can tube laser cutting bring to your operations?

• High laser cutting accuracy and efficiency

• Capacity to process large volumes

• Fast laser cutting speed and flexibility

• Reduced processing costs

HIGH-CUTTING EFFICIENCY WITH LASER CUTTING MACHINES

Get In Touch

Benchmark can offer you the level of support and scale of services to suit your exact needs. Contact us today to discuss how we can help you with your metalwork project.

Our state-of-the-art tube laser cutting machines are CNC controlled and programmed by 3D CAD/CAM software, allowing to process complex shapes including mitres, cod mouths and special profiles.

Our 120,000sq. ft. production facility in the UK boasts advanced laser cutting processes, using the following laser cutting machinery to offer quick and precise laser cutting solutions:

- ADIGE - FIBER TUBE & SHEET LASER

- ADIGE - CO2 TUBE & SHEET LASER

Interested in our laser cutting services? Our specialists can help.